Here it is! A copy of the interview, questions and answers, I conducted with Joe!

What does a quality control chemist do?

- quality control: testing samples of raw materials or products either in mid-stage or close to final stage to make sure that they are of high enough quality, reaching the standards and qualifications, before the product can be mass produced

- research and development of products

- perform various chemical methods and procedures in the lab

Specifically, what company do you work for, what is your official title/position, and what are your duties?

- lead chemist: works in the lab, chemical reactions, testing the products, analyzing, quality control of raw materials to match all the qualifications/standards, quality control of final product, whereas the chemical engineer does the processing and development of the product

- company: Javo-Mex (soap/detergent/bodywash/handsoap/cleaning products company; manufacture for P&G, Mr. Clean)

Could you describe your typical day at work?

- take samples of raw materials or the finished products to the lab for analysis

- follow different chemical methods to do analysis to make sure samples have reached qualifications

- if not reached qualifications, must tell the supervisors and stop production to find the problem

- Inspect other co-workers

- fill out a sample report (raw materials, final products have different reports)

- if the raw material/final product/mid-stage product is poor: give the report to another department

- once final product is approved, send to packaging department and then they will ship it out

- once raw materials are approved, send to processing/manufacturing department to make the product

What is your work environment like?

- in a company laboratory

- must always be sanitary

- sometimes if there were a problem, had to go to manufacturing department

- go to warehouse to sample the raw material

- get finished products from the production/manufacture line

Who do you work with directly?

- director of the quality control department

- chemists, chemical engineers, mechanical engineers, electrical engineers (if manufacturing has problems, they may consult me, or chemist consults them)

What are some of the challenges you face at work and how do you overcome them?

- understanding all the chemistry, following the manufacturing/production rules and standards

- when something is wrong with the raw materials:

- if sample is not good, call the raw material manufacturing company, and send back the materials

-when something is wrong with the final products:

- if sample is not good, keep hold of product and find out the problem by contacting the different departments

- solving the problem is hard; meeting with different departments to solve the problem

- tracing back to the processing stages of product

Around how many hours do you work per day, and how many days per week?

- during the "high season" (summertime; higher demand) : overtime --> 10 hours or more

- regular season: 8 hrs

- during "slow season" : 8 hrs

What is your favourite part about being a chemical engineer?

- the chemistry knowledge you get to apply

- the technology

What is your least favourite part about being a chemical engineer?

- exposure to toxic/poisonous materials (not healthy for the workers)

- boring routine, doing same thing over and over, monotonous

What are your skills and attributes that make you fit for this job?

- knowledge of chemistry

- chemistry or chemical engineering degree

- communication

- attention to detail

Can you go over the QC chemist-specific technology you use?

- different types of instruments: HPLC (high performance liquid chromatography), Infrared spectrum, viscometer (specifically rotational), colorimeter, pH meter

- use computer analysis with HPLC

What are some of the "chemicals and substances" that you utilize and what are they used for?

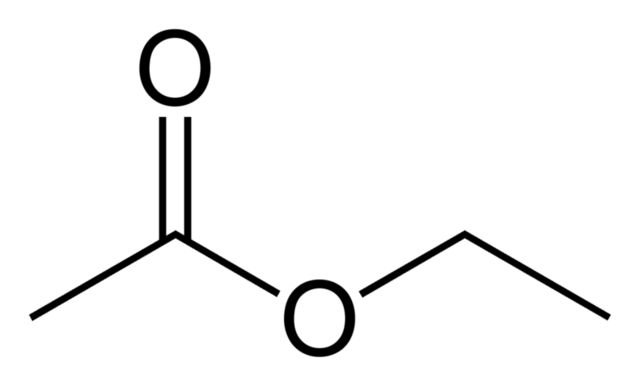

- sodium hydroxide --> adjust pH, hydrochloric acid --> adjust pH, sodium chloride --> adjust the viscosity (for hand soap), different kinds of pigments to adjust fragrance and colour, various strong acids and bases, propylene glycol and sodium xylene sulfonate to adjust viscosity, indicators

Could you give me an example of the methods you use in quality control?

- for detergent: check the colour, smell the odour

- check the pH is in the range using pH meter: specific ranges for specific products

- specific gravity is in the range

- check the viscosity with viscometer

- wet chemical method/titration used to check percentage of efficient chemical and concentrations

- micro confirmation test: make sure no bacteria in the product

Can inform me about your educational background and credentials, such as what undergraduate degree you graduated with, master's degree, professional degrees, etc.?

- master's degree in chemistry (specifically in polymer) at University of Detroit

- undergrad degree in organic chemistry in China

Which chemistry courses did you find the most important for your career?

- organic/inorganic chemistry

- analytical chemistry

- physical chemistry

What kind of a chemistry foundation do you need for this career?

- good understanding of organic chemistry, and inorganic chemistry, math/calculations

What specific topics in chemistry does a QC chemist need a good grasp on?

- chemical news, mostly inorganic and organic chemistry

What kind of training is needed before starting the job?

- the company trains me

- specific to the company; must follow the company's methods and tests and their qualifications/standards

- lab skills, and certain methods were required before one could take the job

- familiarize with safety procedures and health hazards during the job

- proper lab technique was perfected with more practice, and consistently doing job

What are some of the health hazards in your workplace, and what are the safety procedures you need to know?

- wear goggles, do reactions in the fume hood, wear gloves, lab coat, safely dispose of chemicals (biohazardous waste)

- benzene, sulphuric acid had to be handled with care

- Material safety data sheets had to read

What do you think is the future for Quality Control Chemists?

- job demand will be strong; because many manufacturing companies need them to "make sure everything is correct"

- demand for high quality/safe products always high

- or else products will not be the right quality and potentially dangerous to the public

- high standards for cleaning/hygiene products calls for more QC chemists

How do you think your field will advance as technology advances?

- using more highly technological instruments rather than traditional lab techniques

- more efficient, more accurate, faster

- have to learn more new technology (computers, instruments)

- will become large part of career

Would you be able to tell me what your annual salary is around?

- varies depending on many factors

- $50,000-100,000